Clarke CPS160 Review

The new Clarke CPS160 is the latest in a series of plunge saws sent to The Woodworker for review, but will it be a match for its rivals? Read our Clarke CPS160 Review.

CLARKE CPS160 160MM PLUNGE SAW

Jonathan Salisbury find outs

I have come to appreciate the flexibility of the plunge saw, especially its ability to cut large sheets into narrow strips without the need for a table saw. Many ‘budget’ tools are considered a throwaway item, but I’m not in favour of this. Clarke aims to provide a good balance between quality, performance and price in the CPS160; at £ for the saw and 1.4m of track, it’s certainly an affordable model.

Out of the box

The saw arrives ready to use, although there are no track clamps. Other brands’ clamps can be used – and they are worth buying, as the ‘proper’ ones do not get in the way like G clamps. Tracks are extruded aluminium alloy plates with channels for saw guidance, to join track together and to house the clamps. Low-friction tape on top provides easily controllable and smooth saw travel and the edge has thick, soft black tape that gets trimmed during the first pass, providing a reference point for subsequent cuts. Kerf alignment can be more consistently and accurately achieved by using reference arrows moulded into the saw’s casing.

In use

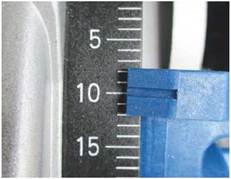

Set the depth to the thickness of the material first. The gauge has clear markings, but when setting the centreline on the stop at 10mm and using the track, a kerf depth of 6mm is cut. It wouldn’t take much to move the gauge to make the centreline the no-track depth and the top the depth with the track! Operation is straightforward; handles are comfortable, the plunge lock button/power switch combination is easy to activate, plunge action is smooth and the saw base glides along the track easily, as long as they are both kept clean.

The motor is noisy (you definitely need ear defenders) and goes from full speed to stop in about five seconds. With a new blade, the quality of finish when rip sawing was as good as expected. The cable is just about long enough to cope with full boards, but must be plugged in close to the work. Efficient dust extraction and chip collection is always going to be problematic with this type of saw, though. Use a vacuum to remove fine dust, but the 34mm/38mm extraction port is opposite the point at which the blade exits the material, so the chips are expelled at the front. There is no kickback prevention, so it’s important to plunge gently as you start; any slack in travel along the track can be taken up by rotating the locking bolts. The blade guard has reference points for starting and ending plunge cuts, although this needs careful planning as location depends on plunge depth.

Mitre cutting

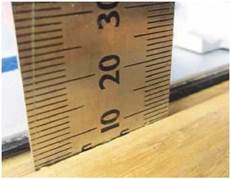

When tilted to cut a mitred edge, the centre of gravity shifts and the saw topples over. The supplied anti-tilt bracket is attached to the base to lock it onto the track, and can be left in place or slid out of the way when not required. The tilting mechanism was set carefully at 45° and the angle of cut is spot on.

All change!

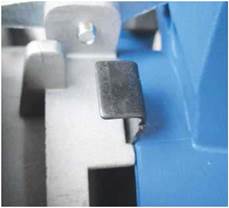

Changing the blade is a bit awkward. The plunge is set at 25mm, but without a depth lock this must be held manually at the same time as operating the shaft lock and loosening the screw. Blades are a standard 160mm x 20mm bore.

The stated blade thickness in the instruction

2 x 700mm tracks might not be enough

A reference arrow indicates the inside edge of the kerf

Depth stop set at 10mm

But when using the track, the depth is only 6mm

The quality of cross cut finish depends on the wood. This is idigbo

Control handles, buttons and triggers are well placed and comfortable to use

Dust extraction could be better

Locking bolts take up slack, if it occurs

Triangles provide guides for starting and ending cuts

Tilting during mitre cutting would be a problem…

… if it wasn’t for the anti-tilt mechanism

booklet is 2.4mm, which refers to tooth width and is different from the dimensions printed on the blade, which give the plate thickness of 1.4mm. There is plenty of choice in the replacement department, but check compatibility carefully. Maximum cut depth is 55mm, which is plenty for most jobs, and allows the cutting of several boards at the same time.

Conclusion

The no-frills CPS160 saw is an entry point into the world of plunge saws and is not without issues, but none that impact significantly on its usability. Until an extraction port is positioned on the front of the guard chips will fly, and it is pretty noisy; the bolt-on anti-tilt bracket is a bit crude, but it works. You need to remember that there is no anti-kickback mechanism, so take your time and plunge gently to avoid issues. The provided 1,400mm of track may not be enough and Machine Mart does not list them, but they are available by contacting the parts department, as are the clamps.

Despite this, it feels right in use, with well- balanced, smooth operation and, since it is a basic model, maintenance is low – keep it clean, give moving parts a light oil every now and then, check that the saw blade screw is tight (but don’t overdo it) and inspect the teeth to make sure they are in good condition. If you are looking for a good quality, simple, affordable plunge saw, then the Clarke CPS160 is certainly well worth considering.

SPECIFICATION

Rated voltage: 230V No load speed: 5,500rpm Maximum depth of cut: 55mm at 90° or 41mm at 45°

Blade dimensions diameter: 160mm; bore – 20mm; thickness – 2.4mm Length of track: two pieces @ 700mm each Sound pressure level: LpA 95 dB(A)

Sound power level: LWA 106 dB(A)

Weight: 7.4kg

Vibration (main handle): 5.72m/s2 Dimensions (L x W x H): 340 x 235 x 260mm

Included: Plunge saw; guide rail assembly (two halves and a joining bar); TCT blade – 160mm 0; tilt protection clamp; tilt protection clamp nut

Web: www.machinemart.co.uk

THE VERDICT

Mitre cuts are accurate – the one here is 45°

The shaft lock doesn’t make blade change very easy

The dimensions on the blade and in the manual

don’t match

Form follows function – the no-frills plunge depth latch